Figure 7.7 The Author observing the box test at Ilmenau University in Germany

The materials to be evaluated are fixed onto a plate at a horizontal distance of 300mm from the electrodes. There are two calorimeters are set in this plate which determine the heat flow densities and are used to judge whether the wearer of clothing made from this material would have suffered second-degree burns. A further requirement is that there is no afterburn lasting for more than 5 seconds and that holes are no bigger than 5mm in any direction. Attention is paid to the total behaviour of the clothing, whether for example the clothing can be opened easily after testing and that fasteners are still functional.

7.5.6 Box Test Output Values

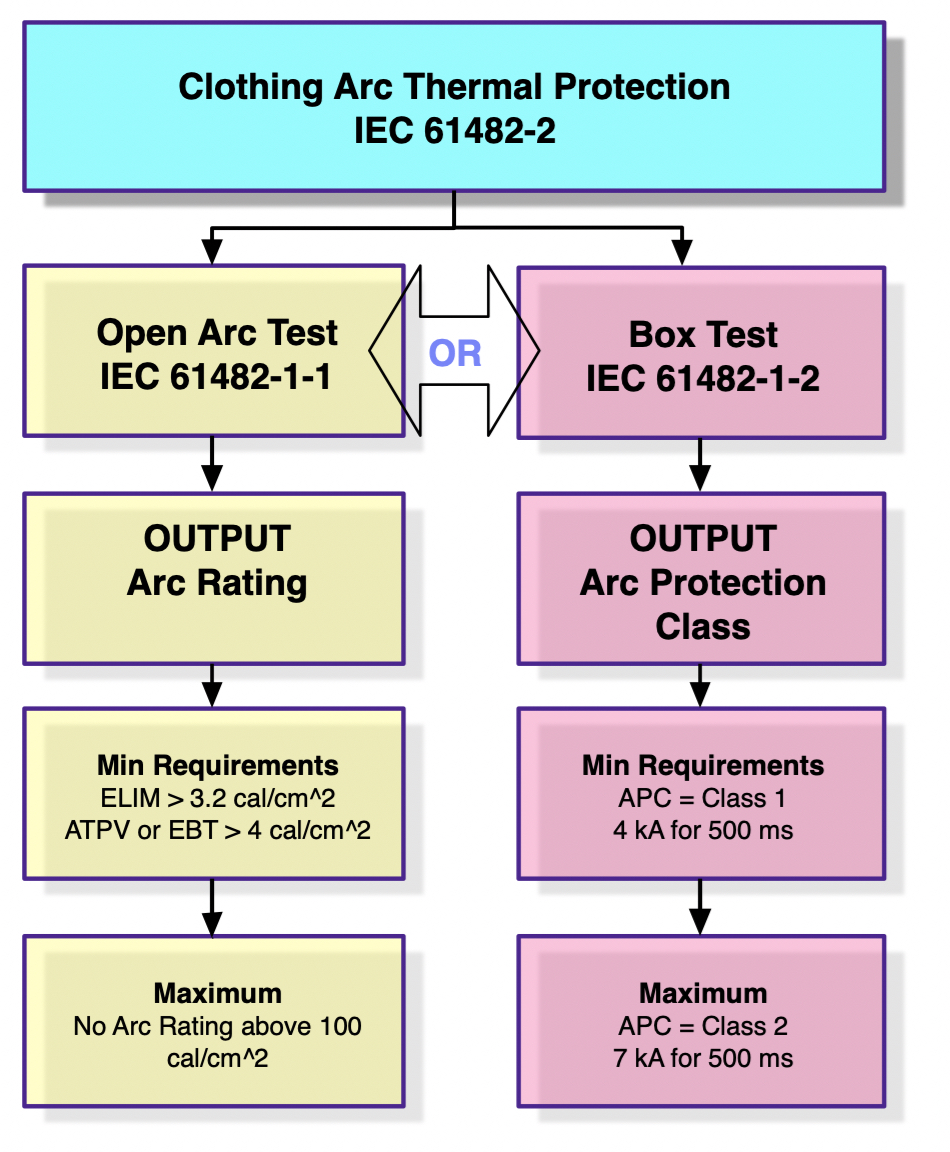

To comply with IEC 61482-2:2018 Live working — Protective clothing against the thermal hazards of an electric arc a material and the clothes made from it must at least pass Class 1 of the "Box Test" in order for clothing from this material to be termed "clothing for protection against thermal effects of electric arcing". (Alternatively, the material must at least have an ATPV of 4 cal/cm2 and the clothing made from it must pass the "Open Arc Test" as described earlier)

7.5.7 Arc protection classes

When tested according to Box Test, the protective clothing made of the tested material is assigned one of two arc protection classes (APC) This will either be APC 1 is subjected to a prospective short circuit current of 4 kA for 500ms or APC 2 at a prospective short circuit current of 7 kA for 500ms. Protective clothing has to demonstrate a minimum arc thermal protection of APC 1 in order to be given an arc rating according to the standard. A fabric will pass the test:

- If the heat transferred behind the fabric cannot cause a second-degree burn. (In box testing, no crossings of the Stoll Curve are permitted)

-

If the fabric passes a visual assessment covering:

- No after-flame time is below 5 seconds.

- No melting to the inner side of the fabric.

- No holes larger than 5mm.

Future visual assessment requirements for head, face and eye protection will probably not allow breakopen, dripping or molten matter inside the protector.

NOTE: The necessary arc protection class is determined by risk analysis. Guidance for the appropriate selection of the arc protection class is provided in other separate guidelines, such as the ISSA Guide and DGUV-I 203-078, Thermal hazards for electric fault arcs – Guide to the selection of personal protective equipment for electric work. There is a calculator which is available through this guide on ea-guide.com. In addition, some further assistance in predicting arc severity for Box Test PPE can be found in Chapter 14: Hazard and Severity Calculators. My opinion is that APC 1 or 2 ratings may be the basis for the selection of PPE, as long as the actual expected exposure situation can be considered to be less severe than the specific exposure condition simulated during the box testing according to IEC 61482-1-2.

7.6 Summary of Minimum Arc Thermal Performance for Protective Clothing from IEC 61482 -2

In summary the following diagram, Figure 7.8, shows the minimum requirements that protective clothing will need in order to meet EN 61482 -2.

Figure 7.8