7.2 Selection of PPE

Article 5 of Directive 89/656/EEC clarifies that assessment of personal protective equipment shall involve an analysis and assessment of risks which cannot be avoided by other means. In respect of arc flash, to start off with a quantitative assessment based on incident energy will go some way to satisfying this requirement. Before choosing personal protective equipment, Article 5 asks us to assess whether the PPE that we intend to use will satisfy the following requirements.

(1) Personal protective equipment must comply with the relevant community provisions on design and manufacture with respect to safety and health. All personal protective equipment must:

- Be appropriate for the risks involved, without itself leading to any increased risk.

- Correspond to existing conditions at the workplace.

- Take account of ergonomic requirements and the worker's state of health.

- Fit the wearer correctly after any necessary adjustment.

(2) Where the presence of more than one risk makes it necessary for a worker to wear simultaneously more than one item of personal protective equipment, such equipment must be compatible and continue to be effective against the risk or risks in question.

The assessment to meet the above requirements involves a three-step process as follows: (Note, that the italics are guidance on how that step can be implemented)

-

an ANALYSIS AND ASSESSMENT of risks which cannot be avoided by other means.

HOW? By predicting the severity of the arc. See Chapter 14: Hazard and Severity Calculators. If the risk assessment has been carried out in accordance with four P’s principle, we are left with a residual risk which will be as small as possible making the next steps easier and lead to a more comfortable and less expensive solution. At this stage we will have a numerical value for the incident energy at a working distance and also an arc flash boundary which will give a distance at which no PPE is necessary. It has to be remembered that different parts of the body will be affected in different ways. If you use the tools available with this guide, you will be able to instantly determine the incident energy at any part of the body in a dynamic way. For instance, the hands may be closer to an arc and have a much greater magnitude of incident energy. (Alternatively, if undertaking an assessment under the IEC64182-1-2 Box test method we will arrive at either an arc protection class (APC) 1 or 2) -

the DEFINITION OF THE CHARACTERISTICS which PPE must have in order to be effective

against the risks referred to in (A), taking into account any risks which this equipment itself

may create.

HOW? Whilst the arc flash attributes can be established by straightforward calculation there are other characteristics that need to be considered before we can go to the marketplace with a shopping list for suitable PPE. For instance, the PPE may be required in a clean room environment, or where there may be a biological hazard or outdoors or perhaps a very dirty area which may degrade or compromise the type of FR materials available. This needs to be identified as environmental considerations. Finally, the characteristics need to include all the other risks that have been identified previously such as ergonomics, compatibility with other protection and fit. -

COMPARISON OF THE CHARACTERISTICS of the PPE available with the characteristics

referred to in (B).

HOW? CE marking is essential so should be the starting point when making comparisons in the marketplace. There have been great developments in the design of PPE systems in recent years and systems are available for parts of the body of environmental conditions. However, depending upon the environmental considerations and other risks, there may have to be compromises when considering the available choices. One of the issues that will crop up when choosing FR fabrics will be how the flame resistant qualities are achieved. There are permanently treated fabrics, predominantly cotton which is chemically treated and then those that are inherently flame resistant. There will be fabric weight, comfort and life expectancy all this is dealt with in a later section as will CE marking.

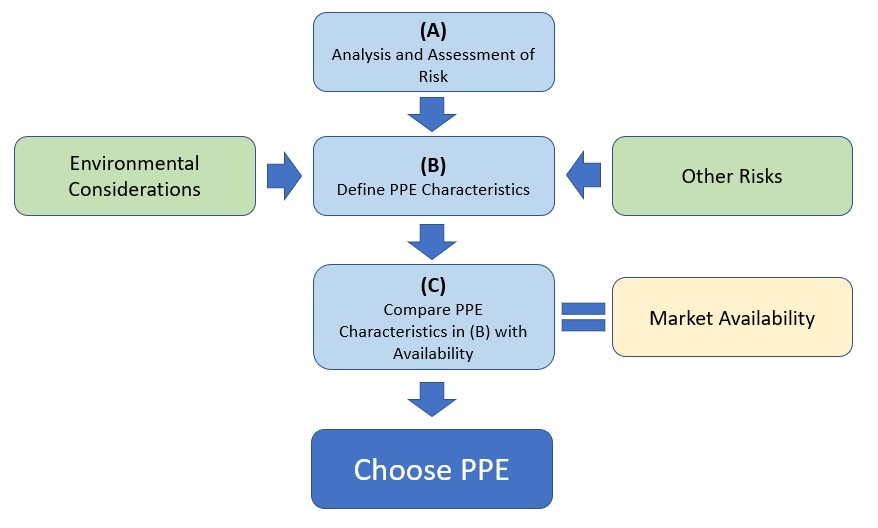

In summary, the following diagram Figure 7.2 shows the above three step process.

Figure 7.2 PPE assessment flowchart

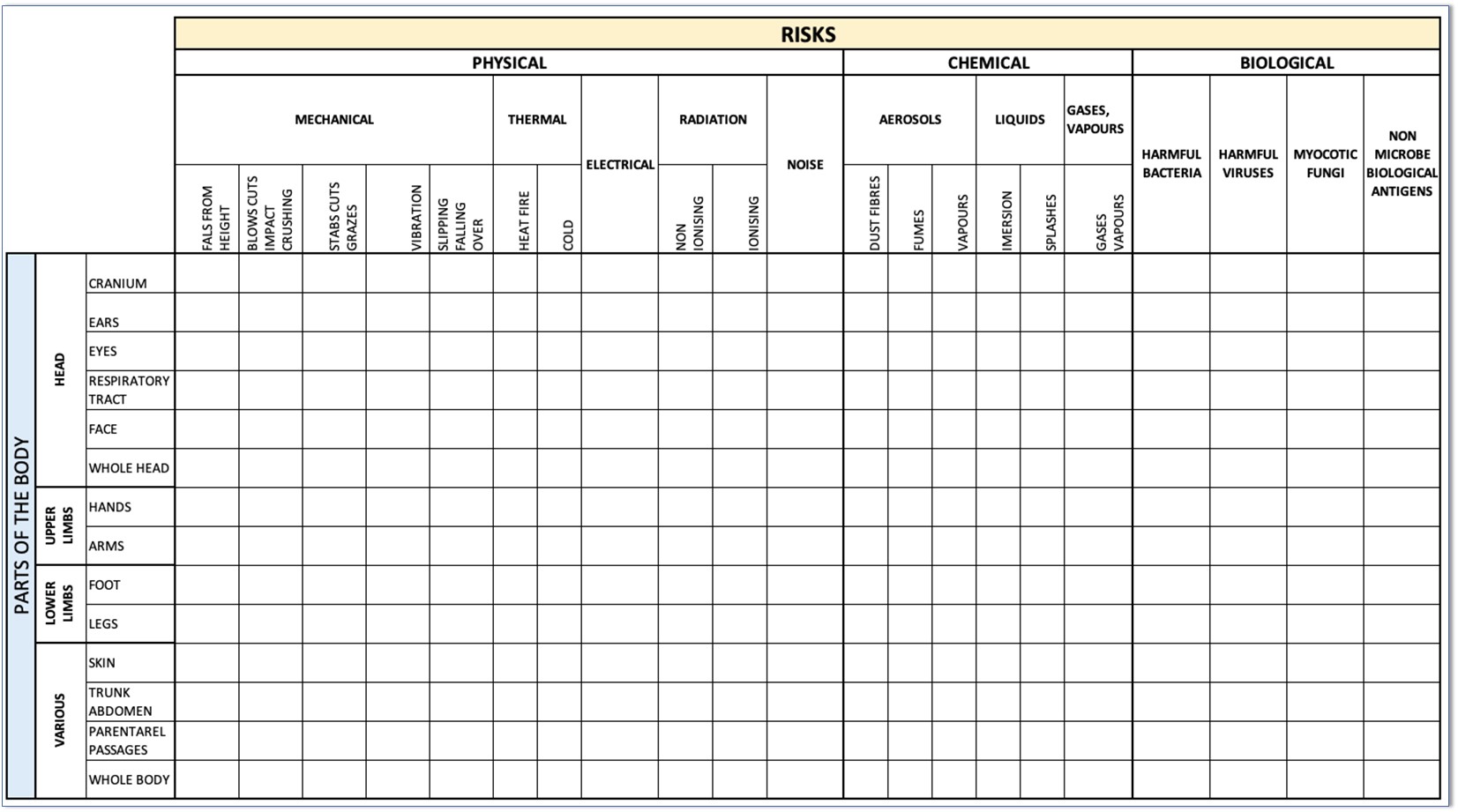

The following table is reproduced from Article 5 of the 89/656/EEC Use of Personal Protective Equipment Directive. This will aid the aid in the identification of all hazards.

Figure 7.2b Risks table

Personal protective equipment is, in principle, intended for personal use although the PPE directive gives the possibility for it to be worn by more than one person by ensuring that this does not create any health or hygiene problem. I would very much doubt if that would be acceptable nowadays.

In addition, the employer must consult the workforce every step of the way. I cannot stress how important that this is when choosing arc flash protection and when carried out correctly, it has a positive effect on morale and eradicates misuse and non-compliance. There is a good example of how this can be done in Chapter 11: Electrical Utilities. It describes the journey taken to equip the entire workforce at Northern Powergrid with new FR uniforms and where worker involvement was a study in how it can be done well. Notwithstanding the case for worker involvement from a sensible management perspective, the “Framework Directive” (European Council Directory 89/391/EEC (EU Workplace Health and Safety Directive)) states that workers shall be informed of all measures to be taken with regard to the health and safety of workers when PPE is used by workers at work. The “Framework Directive” also mandates that there shall be consultation of workers and participation by them in all matters relating to the provision of PPE. As a minimum, the employer must first inform the worker of the risks against which the wearing of the personal protective equipment protects him. The employer shall then arrange for training and shall, if appropriate, organize demonstrations in the wearing of personal protective equipment.