6.10 Dynamic Risk Assessment Checklist

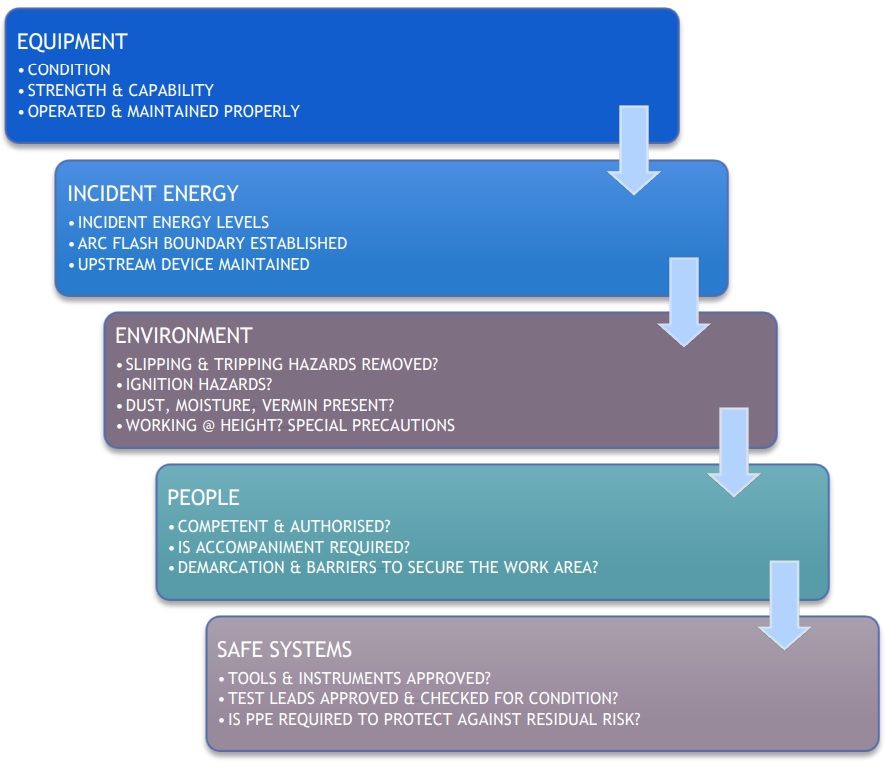

Having identified the hazards arising from the live work, you then must decide how likely it is that harm will occur and the severity of injury that might occur. The following is a check list, Figure 6.6, of issues to consider that may impact on the likelihood of the hazards causing harm.

Figure 6.6 Risk Assessment Checklist

6.10.1 Equipment

ALWAYS ASSUME THAT EQUIPMENT OR CONDUCTORS ARE LIVE UNLESS PROVEN DEAD!

Has the equipment been checked and is it in a safe condition? Check whether the equipment to be worked upon has been examined and in a safe condition for work. Live work should never be permitted where there are any doubts about the safety of cables and electrical equipment being worked upon or adjacent to those being worked upon. The examination can be visual but also using other senses. Smell and hearing can detect burning or electrical discharge. Signs of vermin, birds or organic growths inside switchgear or water ingress is a definite prompt to stop and investigate when the switchgear can be made dead and isolated. Approaches should never be made to damaged cables. Check that the equipment doors, panels and covers are closed and secured and there is there is no evidence of impending failure.

For new equipment, the person undertaking the risk assessment should be confident that the equipment has been professionally installed in accordance with the design specification and manufacturer’s instructions. For existing equipment, in addition, a judgement should be made that it is being maintained and is operating in accordance with the design parameters. Is the equipment over stressed? An arc flash study if properly conducted will provide a single line diagram, a protection coordination study and assure that the strength and capability of the equipment is adequate.

If the equipment is in a safe condition the next step is to consider whether the equipment is finger safe. If the equipment is not finger safe, can measures to prevent contact with live parts be implemented? The term “Finger Safe” is defined as no exposed live parts that can be accessed by solid objects greater than 12.5mm as given by IP rating IP2X.

Do not rely purely on the original specification of the equipment. Insulation is often removed and not replaced. If it is not finger safe, or other measures cannot be introduced to prevent contact with live parts then proceed no further.

If a maintenance program has been implemented as suggested earlier in this chapter, there may be established risk control measures to be adopted when working on a particular piece of equipment. These controls may be displayed in the form of labelling on the equipment which should be taken into account in this risk assessment process.

6.10.2 Arc Flash

A major objective of this guide is to provide the predictive tools to determine the arc flash hazard and the means to prevent it causing harm. As part of the risk assessment, the degree of harm may be predicted and quantified in terms of incident energy and distance. This is very useful, particularly on low voltage equipment where interactions with energised equipment and cables are countless and the relative severity of the hazard has little to do with nominal current ratings or available prospective short circuit current. (See Chapter 12: Myths and Mistakes)

By using this guide and the tools for determining the incident energy, a quantitative analysis can be made about the severity of a possible arc flash which will have a bearing on this decision-making process and also provide the specification data on any protection requirements. The conclusion may be that the incident energy levels are too high and cannot be suitably controlled but experience shows that preventative measures can be formulated in the majority of cases at low voltage.

Using the IEEE 1584 Guide for Performing Arc Flash Calculations, the incident energy level at a distance to the worker is determined. The distance is normally to the head and torso but the calculators with this guide can easily be used to determine the incident energy to other parts of the body and particularly the hands. Where the arc flash hazard is dependent upon tripping time for the upstream protective device, there needs to be confidence that this has been adequately maintained?

Boundaries

It should be ensured that adequate clearances are established and maintained when working on or near to live equipment. Annex A of BS EN 50110-1:2013, Operation of Electrical Systems, gives guidance for shock protection distances in air for working procedures. As we are speaking about low voltage systems here, any contact either by the worker or tools/instruments is classed as live working. Any encroachment below 300mm from the live part below 1000 volts, is classed as “work in the vicinity”.

Using the IEEE 1584 Guide for Performing Arc Flash Calculations, the arc flash boundary can be determined. This is defined as a distance from a prospective arc source at which the incident energy is calculated to be 5.0J/cm2 (1.2 cal/cm2) The significance of this figure, is that this amount of thermal energy is calculated to have a 50% chance of a second degree burn to bare skin if sustained for 1 second. This value is used by many standards as the benchmark that defines protection against the thermal effects of arc flash and the threshold of a zone. For instance, working on or near energised equipment within the arc flash boundary will require the wearing of arc flash PPE. The calculation of the arc flash boundary is very useful regardless of whether prescriptive standards may be applicable in determining the level of harm from the arc flash hazard at a determined distance. For further information, See Chapter 14: Hazard and Severity Calculators.