5.3.4 Arc Flash Detection

Another protection method that has been developed uses an optical sensor that detects the ultraviolet light emitted from an arc flash and causes the protective device to instantaneously trip. The method monitors the current into the equipment that is protected by the optical sensors and combined with the ultraviolet light flash from the arc and the abnormal spike in current it will quickly remove the power source and prevent serious damage. Operation time is extremely fast, usually less than 10 milliseconds plus the time for the circuit breaker to clear the fault which is typically around 60 milliseconds. The system has grown in popularity over the last 10 years, and I have seen it retrofitted to very old high voltage switchgear and also to new low voltage factory-built assemblies. The main manufacturers claim tens of thousands of installations worldwide citing the fact that they are a very cost-effective alternative to traditional busbar differential schemes on medium voltage switchgear.

5.3.5 Active Internal Arc Protection

Several manufacturers have produced innovative ways of reacting to an arcing fault by effectively creating a zero-impedance short circuit across the busbars of equipment. Sometimes the energy is dissipated to earth. Depending upon the method used for sensing the development of an arc, they can be incredibly fast and claim disconnection times as low as 4 milliseconds. They are built to withstand voltages above 40 kV and can handle prospective currents of up to 100 kA.

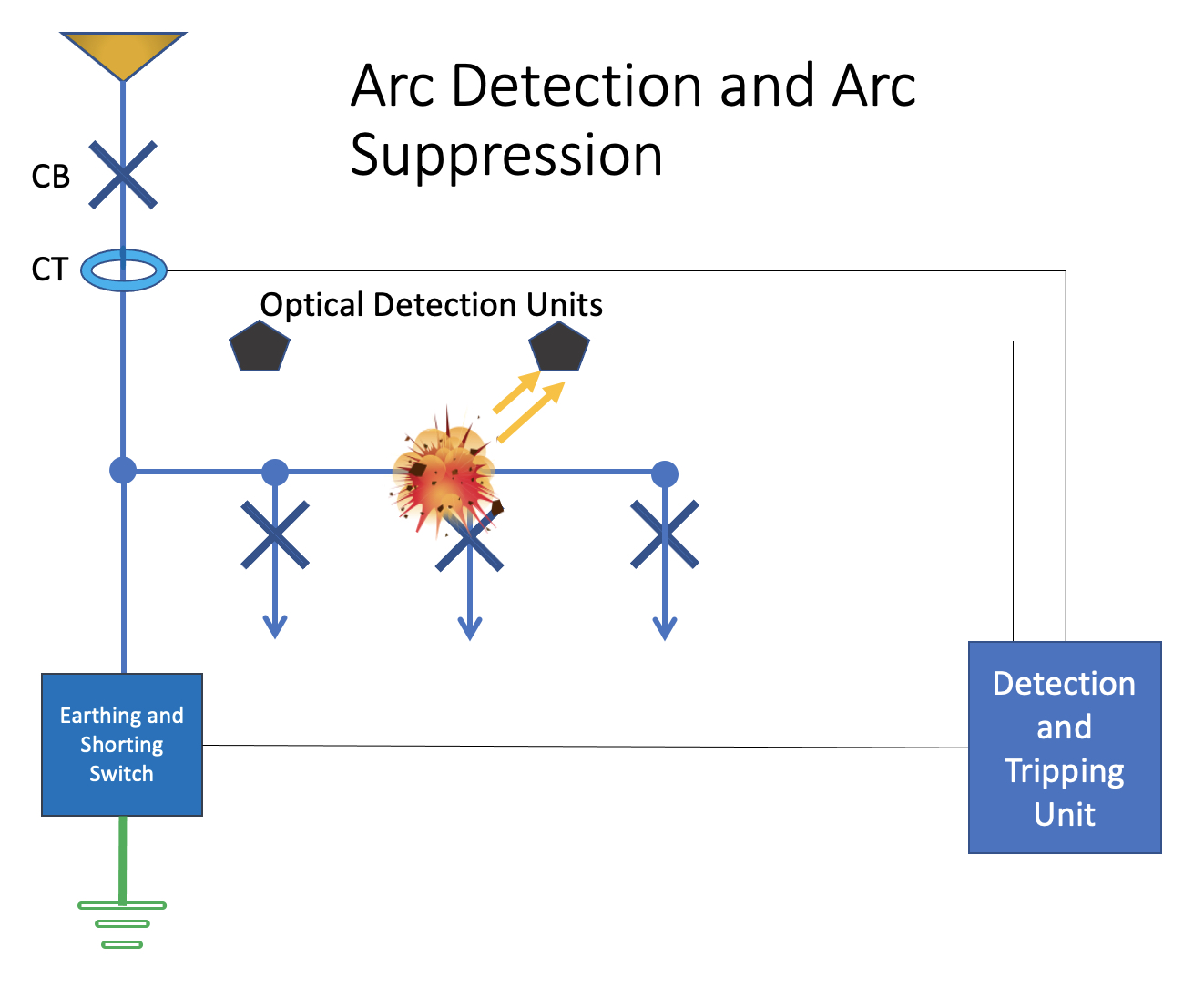

Figure 5.9

In Figure 5.9, there is a diagram of a system that uses arc detection utilising current and optical sensing as described previously. The arcing fault is detected by the current detection unit and simultaneously by the optical sensors which then establishes a three-phase, metallic short-circuit at the earthing switch. The resulting controlled flow of earth fault current is then finally shut down by the feeder circuit-breaker. This all happens almost immediately and whilst there is the expense to consider, the resultant damage from an arcing fault is almost nullified. This means that the equipment can be put back in service quickly resulting in reduced downtime.

5.3.6 Arc Fault Detection Devices

Although Arc Fault Detection Devices (AFDDs), also called Arc-Fault Circuit Interrupter (AFCIs), are primarily aimed at fire safety, the common thread here is that they protect human life from the effects of arcing. The detection and clearance of arcing faults before causing injury or damage is at the heart of much of the beneficial research that has been centred around the arc hazard. Although the technology has been around for over 20 years and required by US and Canadian standards for many years, it has recently been adopted in Europe. In Germany AFDDs are required in hospitals, nurseries and high value buildings. Conventional circuit design has centred upon the clearance of zero impedance short circuits and earth fault current, neither of which will clear all dangerous low-level arcing events. Earth fault protection will pick up line to earth arcing faults but not line to line parallel faults or series faults (i.e., those involving wire breaks) For that reason, AFDDs are worth a mention here to inform of the existence of the technology and possibilities for the future in arc flash detection.

AFDDs work by continuously monitoring the wave form of the current which flows in the protected circuit. Arcing current presents itself as a high frequency and the electronics within the AFDD can differentiate between arcing fault current and those arcs that are produced by switches, contacts, thermostats, carbon brushes, etc...

Currently, the typical cost of an AFDD is in the region of £150 per device which is why they tend to be selected for high-risk situations for instance, premises with sleeping accommodation, risk of fire due to the nature of processed or stored materials, thatched or timber-framed buildings and high value locations such as museums and listed buildings. Most manufacturers provide combined arc fault, over current and earth fault detection.

They are aimed at final circuits at present, up to 63 amperes, so not an option for high incident energy situations. However, one large manufacturer told me that that current capacity will expand in the future.

5.4 Switchgear Design

Designing out the arc flash risk is high ranking on the hierarchy of risk control and above safe working systems, signs & labels and personal protective equipment. It is not however, a silver bullet which will guarantee safety on high power electrical systems. Things change and people change things. For example, throughout the lifetime of any piece of equipment, it may be subject to unforeseen environmental changes creating stress or damage to equipment and/or human interventions which will fundamentally undermine the way in which the original design purpose was intended for. The design, however well intentioned, needs to be a part of the safe systems, safe people and safe place’s philosophy. This requires a holistic approach taking into account factors which will influence safety over the lifetime of the equipment. It cannot be over emphasised how important communication is in the provision of distribution design philosophy.