9.4.4 Option 4. Buy Software and DIY.

I know individual duty holders who have purchased their own software and have successfully carried out studies on their electrical networks. There is, however, a learning curve if you have not had previous experience with electrical modelling software. If this is a course of action that you are contemplating, the following questions may help in the decision:

- Have you read Chapter 13: Complex Software Guide?

- Have you tried the software? You can test drive most software packages for a month. It is worth it as the user experience is very different between different companies.

- Do you know the true cost of the software? I have explained how this can be mitigated in my Chapter 13: Complex Software Guide. You need to factor in the ongoing support.

- Have you looked at leasing the software?

- How many licenses do you need? If the software is going to backup dynamic risk assessments, then additional licenses will be required.

- Training. Do you know what the training costs will be? If you are a newcomer to complex system studies, it is important to get training which can be quite expensive. I would recommend that this cost is factored in before making a purchase.

- Is local support available? This is quite important for the newcomer in particular when applying software to local switchgear norms and local regulations.

9.4.5 Option 5 Long Hand Calculations.

All the calculations that are used in this guide or from complex modelling software are derived from the IEEE 1584 Guide for Performing Arc Flash Hazard Calculations or the ISSA Guideline for the Selection of Personal Protective Clothing when Exposed to the Thermal Effects of an Electric Arc. Practical training is available to help with the understanding of the IEEE 1584 calculations, and much more, from Jim Phillips of brainfiller.com. Jim provides students with worksheets that will allow them to calculate incident energy and arc flash boundaries from first principles. It is also a great way to learn more about the hazard and can be highly recommended.

9.5 Prioritisation

As I have said may times, arc flash is a hazard that should be treated in the same way as any other. The goal must be to prevent the hazard from causing harm and should there be any residual risk, then to provide protection for workers through lightweight solutions. However, there is no need to wait for system studies to be carried out to prevent injury. My advice is, do not delay, start managing the risk right away or A.S.A.P.

9.5.1 The A.S.A.P Principle for Duty Holders

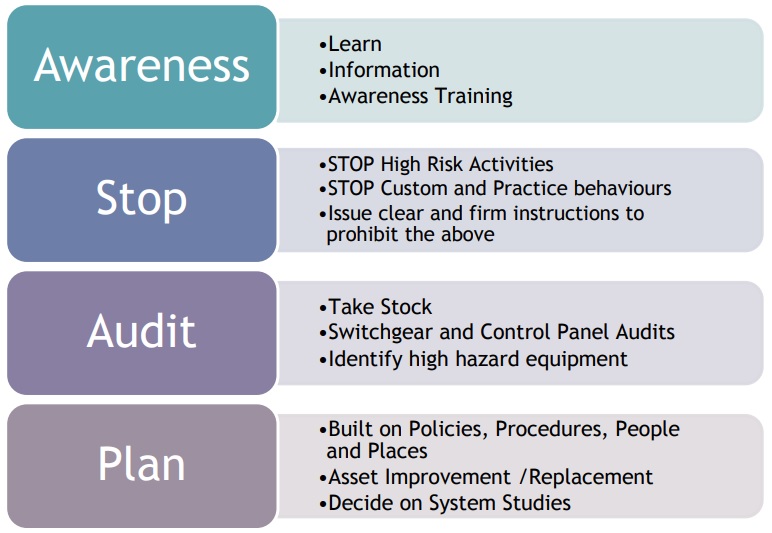

By the ASAP Principle (As Soon As Possible) what I am trying to emphasise is that you do not have to wait for consultants or complex software before you start to reduce risk from the arc flash hazard. You can start straight away. The following ASAP steps will help you to get started.

Awareness: Read the guide, discover the conditions and actions that commonly lead to arc flash and the injury and damage. For operatives this can lead to the step change in attitude that will be required to working safely.

Stop: Stop or avoid those activities that are high risk that arise out of the awareness step. Take decisive action, do not tolerate or turn a blind eye to custom and practice habits that often lead to unsafe working. This step can be implemented very clearly and effectively by issuing simple instructions.

Audit: As I have quoted before; “If you can’t measure it, you can’t manage it.” From experience, equipment and control panel audits can be a very effective way of taking stock and will paint a picture of the effectiveness of existing risk control, housekeeping, maintenance, dilapidation and identification of unsafe practices or equipment. It will also provide a means of determining the arc hazard level very quickly if using the tools provided with this guide. See Chapter 14: Hazard and Severity Calculators.

Plan: Create a plan which looks at a review of policy, procedures, people and places. From the information gathered, look to providing the leadership and strategy to amend rules, asset improvement or replacement and at this stage, decisions can be made to commission an arc flash study if necessary.

To summarise the above:

The first two actions, awareness and stop will in my view be the biggest step change that one can make and can often create good returns fairly quickly. The audit stage can provide the catalyst for change by shining a light on existing work practices and equipment and if carried out effectively, will feed into the fourth stage of planning.